The climate crisis, the depletion of resources and increasing pollution highlight the need for a model of circular economy (1) in the European continent, and through this, the establishment of a cycle where materials, products and resources can be reused and recycled.

PLOOTO project (2) is at the forefront of circular, innovative, applicable solutions, where a Circular and Resilient Information System (CRIS) can support manufacturers in their green, digital and circular transition. The goal is to promote waste reduction and product traceability to the entire end-to-end process of the Secondary Raw materials (SRM) through interconnected digital services, real time systems for decision-making, monitoring and creating product passports.

The main objectives of this project are the following:

- A transformation framework, used for traceability regarding materials and products, for referencing processes aiming to define new products and for building governance models for managing circular value chains

- ICT tools to model products, processes, supply chains and connect digital twins

- A sustainable scorecard where various Key Performance Indicators (KPIs) are defined and analyzed.

- Data management and analytics systems.

Out of the above-mentioned objectives, in manufacturing, data management and analytics take a prominent role but also face significant challenges. Firstly, data needs to be collected from diverse sources with missing values, following a multitude of evolving, mutually incompatible standards. Secondly, in a circular economy, business data from different actors need to be exchanged, highlighting the need for security. Thirdly, adoption of data and analytics systems tends to be low since existing systems are often challenging to deploy and use, and become too costly to maintain due to their complexity, which can negate the potential benefits of advanced analytics. Finally, validation of the insights with industrial partners is needed to ensure the practical applicability and reliability of the insights generated, to support manufacturers in making timely, informed decisions.

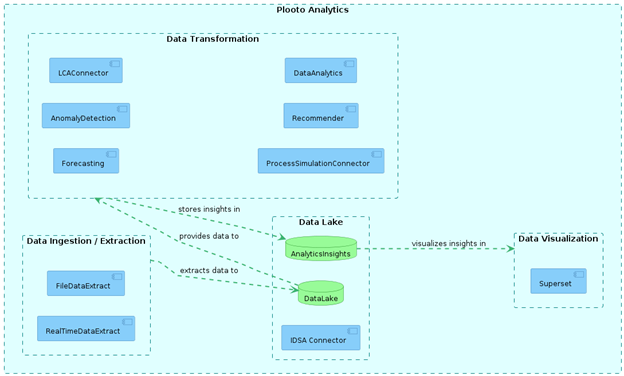

At Frontier Innovations (3) we have designed and developed a data management and analytics solution for circularity, that addresses the above-mentioned challenges. A conceptual overview of the proposed component can be found in Figure 1.

Figure 1: Conceptual Overview of Data Management and Analytics

To address the topic of data collection and interoperability, a dedicated data model has been designed to fulfill the needs for storing diverse types of manufacturing information about organizations and manufacturers, including static and dynamic data for both historical and real-time purposes, assets, and measurements information in industrial processes. We have implemented an extraction service to validate and harmonize data that is coming from different external sources, such as external services, IoT devices, or even files that are extracted from a manufacturer or another organization. In the case of missing data, we utilize machine learning for creating synthetic data based on the available datasets. These synthetic datasets serve multiple purposes, including filling missing values, testing system performance with a larger volume of data, validating machine learning models, and providing initial forecasted values in industrial processes.

To address the topic of security, we use well-known standards for data exchange. All exposed REST APIs are secured using pre-shared tokens and are protected by firewalls, and the storage of data takes place in encrypted volumes, thus supporting comprehensive data protection in transit and at rest. Moreover, our system is designed to be extensible and compatible with IDSA-enabled data spaces (4), including a standardized secure process for data exchange negotiation and formal agreement between organizations before the actual transmission of any data.

Our choice of technologies, combined with a standardized internal data model and the usage of commonly accepted standards, helps to support a portable, easy to deploy, and maintain system. By leveraging containers and portable databases, our solution achieves high portability across different settings, enabling a scalable and reliable system that can be deployed in multiple types of infrastructure, whether cloud or on-premises. To support the end user, a dashboard is provided, allowing the monitoring and analysis of all available data, giving a comprehensive view of the processes and their status, together with insights such as forecasts and anomalies detected, supporting decision-making.

Finally, working with ASPIS (5), we validate the quality of the insights provided by the system. Based on the data maintained in our system, Frontier has developed and validates an anomaly detection algorithm using machine learning technologies to continuously monitor data streams and trigger alerts whenever anomalies are detected. Early detection helps in preventing issues such as component malfunctions or problems in the manufacturing process that may lead to serious damage in the future.

The PLOOTO Data Management and Analytics component is evolving into a comprehensive solution that integrates not only Data Ingestion, Transformation, and Visualisation, but also provides connectivity with Data Spaces, Lifecycle Analysis, and Process Simulation Modeling components. Data Spaces technologies support a common framework for secure and interoperable data exchange, while Lifecycle Analysis and Simulation capabilities enable running “what-if” scenarios and evaluating different solutions in terms of financial impact and environmental footprint.

The future of more efficient and sustainable manufacturing is based on digital and circular economy principles. At Frontier Innovations, in PLOOTO project, we keep working to give value to the data, and we support organizations to utilize them and extract insights that help in their development and the improvement of their processes.

(1) Murray, Alan, Keith Skene, and Kathryn Haynes. “The circular economy: an interdisciplinary exploration of the concept and application in a global context.” Journal of business ethics 140 (2017): 369-380.

(2) https://www.plooto-project.eu/

(3) https://www.frontier-innovations.com/

(4) https://internationaldataspaces.org/

(5) https://www.aspis.gr/